Thermal Imaging

Thermal imaging can be an extremely useful tool in conducting energy assessments and audits. It can also be highly effective when used for fault detection.

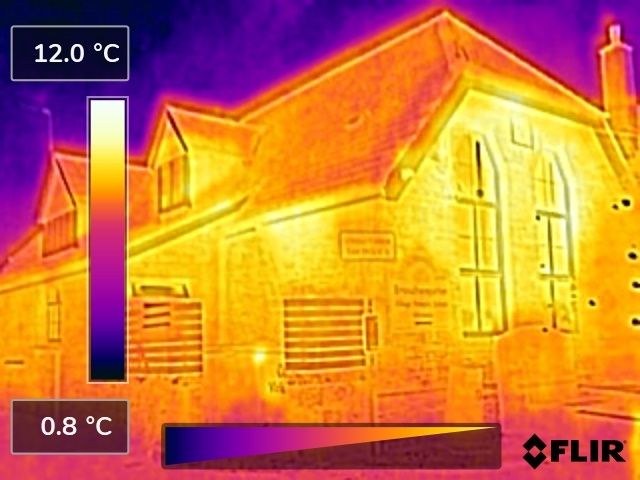

A typical thermographic survey is carried out using thermal imaging to identify heat loss from a building.

This type of survey can identify whether insulation is correctly installed, heating systems are working effectively and if any electrical circuits are overheating. It could be worth considering if your house is cold, damp or draughty, or if your energy bills seem unusually high and you are not sure why.

Thermal imaging is useful for:

- Identifying missing or inadequate insulation

- Air infiltration or leakage (draughts)

- General condition surveys

- Tracing faults or leakage in plumbing or underfloor heating

- Damp and mould detection

- Locating flat roof defects

- Electrical inspections

- Plant or machinery inspection

A thermal image is essentially a visual display of thousands of surface temperature measurements. This makes it easy to see where insulation is defective, air is leaking in or out of the building or where there are issues like thermal bridging or damp penetration.

Thermal imaging surveys can be used on their own as a simple way of locating air leaks in the fabric of a building. They can be combined with airtightness testing in order to quantify the leaks.

Some of the reasons to consider thermal imaging are:

- It is a quick and non-invasive form of inspection

- The results are visual and easily understood

- It can demonstrate compliance with specification

- It can enable sustainability credits in BREEAM

- Quickly resolve arguments with sub-contractors as to where faults are

- Demonstrate the effectiveness of heating and cooling systems

Excessive losses can occur through building fabric as a result of poor design, low-quality materials, poor workmanship, poor maintenance, or changes that have been made since construction. Often these losses will go unnoticed because the problem is hidden within the building fabric. A thermographic survey can be the best (or sometimes only practical) way of identifying the issue so it can be addressed and resolved.

Different materials have different emissivity, and this affects the reliability of readings. It is best to ensure you’re your thermographic survey is undertaken by a professional with the skills and knowledge to adapt the camera and software to suit the specific situation. This way you will obtain the most accurate information from the process.

Use the Find A Member button at the top of the page to locate your nearest Proficiency member.